In the pulp and paper industry, agitators play a vital role in various processes, contributing to the efficient production of paper and paper products. Agitators are used to mix, suspend, and move pulp materials, chemicals, and additives during different stages of the papermaking process. Here are the details of their use in this industry

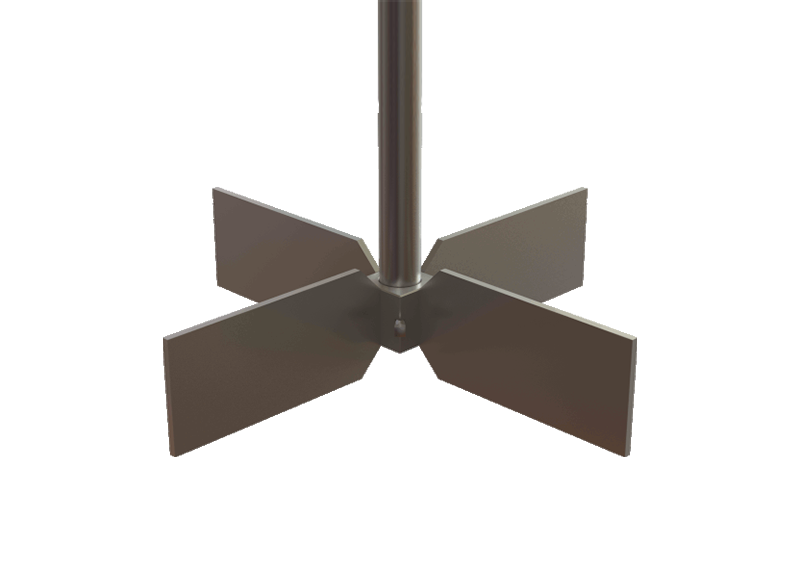

| Impeller Type | Central / off center Baffles: 0 / 2 / 3 / 4 Blades: 2 / 3 / 4 Stages: 1 – x |

|---|---|

| Flow Direction | Radial |

| Preferred Arrangement | Center Mounted |

| Blending | • • |

| Suspending | • • |

| Dispersing | • |

| Heat Transfer | • • |

| Gassing | • • |

| Flow Range | Laminar / Transitional |

| Viscosity Range | 1 - 10,000 |

| Features | - Universal mixing impeller for a wide viscosity range - Variable blade angles (standard versions with 45° and 90°) |

| Diameter Ratio | 0.7 - 1.2 [d1 / d2] |

| Speed | 30 – 300 |

| Tip Speed | 1 − 5 [ft/s] |

- 01. Paddle Blade Design

- 02. Shaft and Mounting

- 03. Adjustable Speed

- 04. Material of Construction

- 05. Mixing Vessel Compatibility

- 06. Mixing Efficiency

- 07. Low Power Consumption

- 08. Versatility

- 09. Seal Arrangements

Overall, paddle agitators are popular choices in industries where gentle to moderate mixing and agitation are required. They are reliable, relatively simple to operate, and suitable for a wide range of materials and processes.

- 01. Performance Testing

- 02. Durability Testing

- 03. Load Testing

- 04. Noise and Vibration Testing

- 05. Efficiency Testing

- 06. Material Compatibility Testing

- 07. Temperature and Pressure Testing

- 08. Contamination Testing

- 09. Safety Testing

- 10. Calibration and Accuracy Testing

- 11. Electrical and Control System Testing

- 12. Installation and Assembly Testing

- 13. Surface Paint Testing

- 14. Welding Quality Testing

- 15. Balancing Testing

- 16. Material Chemical Testing

- 17. Material Mechanical Testing

- 01. Pulping Process

- 02. Bleaching Process

- 03. Mixing Additives and Chemicals

- 04. Paper Coating

- 05. Pulp Chests and Stock Preparation

- 06. Recycling and Repulping

- 07. Fiber Suspension and Flow Control

- 08. Chest Cleaning and Maintenance

Computational Fluid Dynamics (CFD) analysis for an agitator involves simulating and analyzing the flow of fluids and the associated mixing behavior within a mixing vessel or tank equipped with an agitator. This analysis is crucial in industries such as chemical engineering, pharmaceuticals, food processing, and more, where efficient mixing and agitation are essential processes.

Our step-by-step approach to conducting a CFD analysis for an agitator:

- 01. Problem Definition and Geometry Creation

- 02. Mesh Generation

- 03. Boundary Conditions

- 04. Solver Setup

- 05. Simulation Run

- 06. Post-processing and Analysis

- 07. Optimization and Iteration

- 08. Reporting and Documentation